Aluwell always holds the commitment to environmental protection and refuses to use inferior materials to save costs. We enforce strict control to the content of heavy metal in raw materials and adopt the latest EU standard. We have been ROSH certified which proves that our aluminum composite panels (ACP) have no harm to human body and environment.

Aluminum Alloy

To make the sandwich panels, we use the aluminum alloy from China Southwest Light Metal Group which is also the aluminum alloy supplier of Chinese airplane equipment companies. Their aluminum alloys have great tensile strength and T-bend peculiarity, perfect flatness, and have reached the highest international standard.

Paints

The paints coated on our ACPs are supplied by BECKER, PPG, FULLISUN, JINCHAOYANG companies in line with HYLR 5000& KYNAR500 standards. They deliver excellent corrosion resistance and weather resistance. Because of that, our products can keep good appearance whatever they are in extremely hot or frigid weather, even in heavy polluted area. Only by using neutral detergent can you keep the panel as good as new.

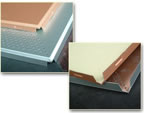

PE Core

We choose the Low Density Polyethylene (LDPE) core from Qilu Petrochemical (QPEC). The production is conducted by high-pressure process (147.17-196.3MPa). It comes with low degree of crystallinity (45%-65%), small density (0.910-0.925), soft light, and anti-impact and anti-low temperature properties.

Adhesive Film

The adhesive films are supplied by Jiangyin Liyuan Group. Liyuan has cooperated with Dupont for more than 12 years history. It is the first company to develop this material. It leads the industry from glue connection materials to high polymer materials.