Coating is an important process during aluminum composite panel production.

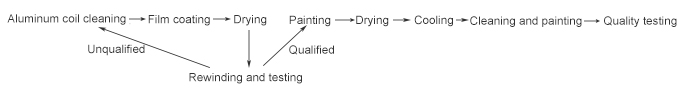

1. Clean the aluminum coil

2. Dry and test the coil while coating the polymer film; reject the unqualified ones and repeat the previous processes until the coils are qualified

3. Paint the qualified coils and dry them again

4. Deliver the coil to the cooling system for cooling

5. Clean and paint the coil once again

6. Test the coil; the qualified ones will be delivered to the next step for lamination

Main Products

-

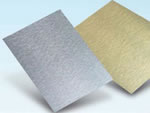

- Wooden Grain Aluminium Composite PanelUsing quality coating materials from PPG and Becker, coating lines and other ACP production lines from Taiwan Alumax, Aluwell is able ...

-

- Brush Aluminium Composite PanelMade using high quality aluminium composite panel production lines from our parent company Taiwan Alumax, Aluwell brush ACP is presented long warranty and reliable ...

-

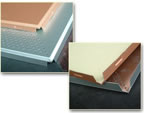

- NANO Aluminum CeilingThe NANO aluminum ceiling is made from aluminum alloy 3003 which features good corrosion resistance and formability. Nano technology is adopted for its surface coating, and in ...

-

- PVDF Aluminium Composite PanelALUWELL PVDF aluminium composite panel consists of a polyethylene core sandwiched between two 0.5mm aluminium skins. As its name suggests, the ...