Nano-PVDF Aluminium Composite Panel

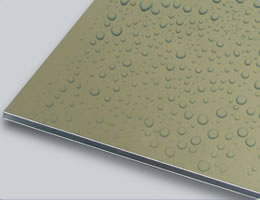

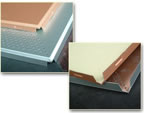

ALUWELL Nano-PVDF aluminium composite panel is anti-graffiti and self cleaning. It is composed of a polyethylene core sandwiched between two 0.5mm aluminum skins. Coming with hydrophobic and lipophobic surface, the Nano-PVDF ACP features good water and dirt resistance. The protected object stays clean much longer and can be easily cleaned with pure water.

The LOTUS EFFECT is the most distinguished characteristic of Nano-PVDF aluminium composite panel. The lotus leaf is never polluted by dirt although coming from silt. The same as lotus leaves, Aluwell ACP has high water repellency and the dirt on its surface can be easily cleaned away by a heavy rain.

Why choose ALUWELL Nano PVDF composite panel?

ALUWELL get a patent for nano-PVDF panel which has the following advantages.

- Excellent easy-cleaning.

- Pollution Resistance

- Oil resistance

- Good Friction Resistance

- Strong Acid & Alkali Resistance

- Outstanding weather resistance

Advantages and applications

Due to above characteristics, the Nano-PVDF aluminum composite panel is ideal for wall decoration and protection for office buildings, shopping centers, industrial buildings, airports, hotels, bus centers, hospitals, schools, supermarkets, and residential buildings, to name a few.

| Aluminum Alloy | AA1100, AA3003, AA5005 |

| Al sheet thickness | From 0.25mm*0.25mm to 0.5mm*0.5mm |

| Panel thickness | From 3mm to 6mm |

| Panel width | 1000mm & 1220mm & 1250mm & 1500mm & 1575mm |

| Panel length | Upon customs' request |

| Color | Upon customs' request |

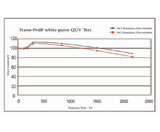

| Coating Type | NANO Coating | PVDF Coating |

| Paint Particle | 0.001micron-0.03micron | 0.3micron |

| Pollution Resistance | Dust hardly sticks on the panel | Dust sticks easily |

| Easy-cleaning | Dust goes away with bead | NIL |

| Friction Resistance | Over 10,000 times | Several thousands times |

| Acid Resistance | 5% HCI, 240 hrs | 24 hrs |

| Alkali Resistance | 5% NaOH, 240 hrs | 24 hrs |

| Oil Resistance | 20# machine oil, 240 hrs | 24 hrs |

| Weathering | Both paints have prominent feature of weather proofing and color retention. | |

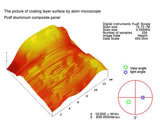

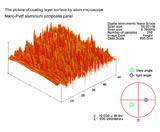

The paint layer comparison of PVDF ACP and Nano-PVDF ACP under atom microscope.

The final result shows that the surface paint structure of Nano-PVDF aluminium composite panel is denser than that of PVDF panels. So, the former keeps better pollution resistance.

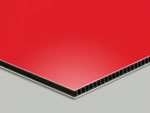

Completed in year 2006 Taken in year 2009

Comparison of buildings finished with Nano-PVDF ACP and Normal PVDF ACP

Real project comparison of NANO-PVDF ACP and PVDF ACP which have been used for 3 years.

From the above comparisons, we know that Nano-PVDF aluminum composite panel is a better alternative to PVDF panel.

As a top ranked aluminium composite panel manufacturer and supplier in China, Aluwell can also produce polyester ACP, fireproof ACP and wooden ACP, etc. All Aluwell building materials are certified by REACH, RoHS, and ASTM, etc. due to our commitment to ISO9001, ISO14001, and ISO18001 standards.

If you are looking for quality and affordable aluminum composite material manufacturers, please don't hesitate to contact us. ALUWELL is the one you are searching for.